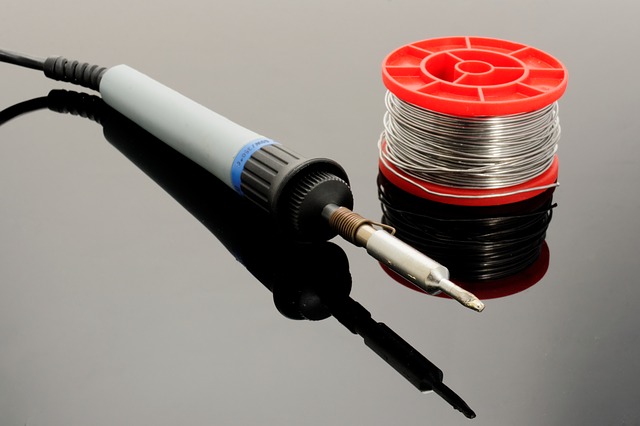

Soldering irons have shown to be an excellent solution for all types of connection troubles between metals, as well as for soldering plastic. A soldering iron is used in a variety of areas, including automotive, plumbing, and electrical circuit boards, to name a few. When users use their soldering iron to melt the solder and repair something they’ve been worried about, they’re overjoyed with their purchase. A dirty soldering iron, seems to be something that no one enjoys using.

Table of Contents

The Reason for the Dirty Soldering Iron

Soldering iron tips come into contact with a variety of different chemicals and accumulate them as residue over time, which is one of the causes behind this. A soldering iron, like all metals, is susceptible to rusting, which is a problem that should be avoided if possible. Using a soldering iron to remove solder from a circuit board will result in the soldering iron becoming dirty as a result of the soldering.

Precautions

Anyone who is new to soldering should be cautious and cautious. It is also dangerous to clean the iron because of the heat. While cleaning, we recommend that you wear protective goggles and gloves. Having a proper ventilation system in place would help to eliminate the fumes from the room better.

Disinfect the parts that are not heated

Make first contact with the soldering iron’s power cable and handle with a piece of cloth or a brush to remove any dust or dirt. Use a damp piece of cloth to remove any remaining tenacious stains or sticky substances from the handle and power cord, then dry the area thoroughly. Please remember to properly dry the instrument before plugging in the cable once more.

Using a Soldering Iron, how do you clean the tip of the iron?

Cleaning the soldering iron’s tip is a little more difficult than cleaning the other elements of the soldering iron. There are various sorts of dirt and debris that can accumulate at the tip, The Soldering Iron Should Be Cooled Before Using The first thing you need to do is make sure that your iron has been properly cooled. Certain parts will require heating in order to remove oxidizing soil later on, but this isn’t one of them. Using a soldering iron, carefully touch the tip after 30 minutes of being disconnected from the power source to determine if the iron is still hot or cold. Keep waiting until the temperature is at a comfortable level for you.

A sponge can be used. Any mid accumulation or other sticky substances that may be easily removed without the use of heat will be eliminated by using this method to clean. The damp sponge also aids in chilling the tip of the pen needle. Utilize Steel Wool to clean the iron tip. When it comes to soldering irons, rubbing the tip with a moist sponge will almost certainly not remove all of the non-oxidizing dirt off the iron tip if you are not a regular cleaner of the iron.

Abrasive cleaners such as sponges or steel wool will be required for some of the more tenacious stains and discoloration. Bring out the steel wool and dunk it in a little liquid. Use the damp steel wool to scrub the iron tip’s body until it is clean. Make sure you cover the entire iron tip by rotating the iron tip 90 degrees.

The Iron Tip is being honed

It is the process of applying tin that is denoted by the name “tinning.” When it comes to soldering, tinning refers to the process of placing an even layer of high-quality soldering tin over the iron tip of the soldering iron. However, we urge that you wear safety eyewear before beginning. Heat the soldering iron while wearing your safety goggles, and then apply a thin and even layer of soldering tin to the soldering iron tip with the high-quality soldering tin you purchased earlier. This will aid in the prevention of rusting of the metal parts.

How can I clean my soldering iron without using sandpaper?

Although you may not always require sandpaper, it is a good idea to keep some on hand just in case. 600-grit sandpaper in a moment, we’ll talk about how to use extra solder or tinner to tin your tip. The sandpaper may be required at this point. Wait until the iron has cooled before sanding the tip till you can see some shine again.

A black soldering iron tip might be difficult to clean

As you work, slowly lower the soldering iron tip into the chemical cleaner, making sure the entire corroded region is covered. Wait until the paste begins to melt around the tip of the needle. After that, insert the tip of the needle into the brass wool and twist it back and forth a couple of times.

When should I use my soldering iron and what temperature should I use it at?

Before you begin, make certain that the surfaces to be soldered are free of contaminants. To begin, turn on the soldering iron and raise the temperature to a level over the melting point of the solder you’re working with. Lead-based solder should be used at temperatures between 600°-650°Fwhile lead-free solder should be used at temperatures between 600°-700°F.

Which solder is preferable – lead-free or lead-containing?

Tin whiskers, which are still present, are reduced in number as a result of the use of lead. When it comes to safety, the most significant dangers are those that threaten the environment, such as pollution.

Soldering in a closed space is acceptable

You may, however, do it everywhere there is electricity. The vapors are completely free of lead. It is important to note that the boiling point of lead is significantly higher than the temperature during which soldering will take place. It is not necessary to breathe the fumes all of the time because they are not extremely hazardous.