Have you ever wondered how a rocket engine, or a simple jet engine works? If yes, then this post is just for you. You will get detailed information about How To Make A Simple Jet Engine At Home. Follow the step by step process, and build your own super cool working miniature jet engine at home? Let us get started.

A jet engine is a movement of gases, for example, like what you see on the video below. The principles of the jet engine was figured out and a patent was issued in 1791 by Sir George Cayley. The scope of this project is to make a simple jet engine at home .

Table of Contents

How to build a simple jet engine

1. Use the small engine of your bike or a drill to rotate the turbine blades. I used a drill in my case.

2. Apply some oil to the bearings and rotate them 10 times to spread the oil in all surfaces.

3. Insert the shaft into the bearing and use two O-rings to keep it inside and sealed (you can also use some glue).

4. Insert the turbine blades using an M4 bolt with nuts, you will need to balance the turbine later, so don’t insert it completely for now.

5. Use PVC glue to attach both parts together, wait 5 minutes for it dry completely.

6. Now that your engine is ready you should test it, first apply some oil in all moving parts then start your bike or drill and let the turbine rotate at high RPM until it get hot (the plastic will have some flexion but don’t worry about that).

You need a compressor

The most important piece of hardware for a jet engine is obviously the compressor. What you’ll want to do is take a hair dryer and attach it to a small model airplane turbine, then put it all in a box so you can’t see it. Just kidding! You’re going to need something more than that.

A real compressor can be made from some PVC pipe, an electric leaf blower and some epoxy. Start by taking the leaf blower apart. You should have something like this:

Next, cut up some PVC pipe so that you have some nice straight sections and glue them all together with epoxy so they form a circular shape. This straight tube will be the compressor’s nozzle.

Now you need to fit your leaf blower into this circle of PVC pipe. Figure out where the intake is going to go on the center shaft, then epoxy it together. Use tape or something else to hold it in place while the glue dries.

To compress compressed air, the compressor is located in the engine.

To compress compressed air, the compressor is located in the engine. This is a long cylinder that has many blades. When air enters the engine, it passes through these blades. The compressor rotates at high speeds and makes moving air more dense than usual.

The combustion chamber is the next part of the jet engine. It allows you to ignite fuel and add heat to the air flow. Gasoline or kerosene can be used as fuel for jet engines. Ignition of fuel starts combustion, which increases the temperature of the gas stream even more.

The next stage is turbocharging. At this stage, the gas expands and becomes less dense. With this, its temperature drops significantly, but its speed remains very high.

The expansion takes place in a turbine that rotates at high speeds and serves as a source of energy for a compressor (compressed air) and other components that work on compressed air (hydraulics).

Take out the heat at this stage!

Jet engines are one of the most fascinating machines ever invented. They work in such a perfect way and are so beautifully designed that it’s hard not to be impressed by them.

Jet engines are quite different from normal piston engines. Even though they both use fuel to make power, they do it in different ways. An internal combustion engine (ICE) creates power by igniting fuel which then pushes a piston inside a cylinder. This is an inefficient process that wastes a lot of energy through heat loss and friction. The jet engine, on the other hand, uses the energy of burning fuel to suck air into the front of the engine and push it out at high speed through the back. This creates thrust forward and allows us to move with great speed.

The fan at the front sucks air into the compressor where it is compressed before being sent to be mixed with fuel and ignited in the combustor. The hot air from this then flows through a turbine which powers the compressor and fan before escaping through the nozzle at extremely high velocity creating thrust.

However, when dealing with machinery, there will always be some losses from friction, drag and heat leakage, meaning that all fuel used by an engine is not completely turned into useful work output. This means that all engines have some efficiency,

The heat takes place in the actual turbine.

The key to powering a jet engine is the combustion chamber, where fuel and air are burnt at high pressure and temperature. The combustion process requires two things: a fuel source and oxygen.

The heat takes place in the actual turbine. The exhaust gases flow through the turbine blades, and as the rotor spins, the heat causes it to spin as well.

The more powerful your turbine, the faster it spins. In a jet engine, the blades are angled so that they push air backward and create thrust that propels the plane forward.

This concept can be applied to any model of jet engine: you will always have a combustion chamber, a turbine and an exhaust.

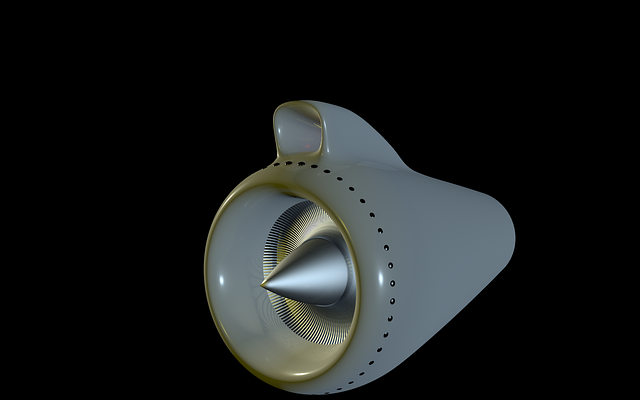

The final component of a jet engine is the nozzle

The final component of a jet engine is the nozzle. This is the part that directs and accelerates the flow of hot gas to create thrust. The first nozzles were simple cones designed to accelerate the gas as efficiently as possible, but it was soon discovered that this design produced too much drag.

The modern convergent-divergent nozzle solves this problem by starting out with a large opening to slow down the gas, then gradually reducing its cross-sectional area until it reaches the optimum speed for maximum thrust. It’s worth pointing out that a jet engine produces thrust simply by accelerating a mass of air and using Newton’s third law to push itself in the opposite direction.

This is why jet engines are much more efficient at high speed; they’re pushing more air in a given amount of time.

Last Thoughts

That’s not to say you should, though. Making a jet engine at home is illegal for a reason, and it’s incredibly dangerous to boot. Also, even if you don’t personally get injured your actions could endanger the lives of innocent people around you.

So be careful stay safe and try to do save experiments at some other places.